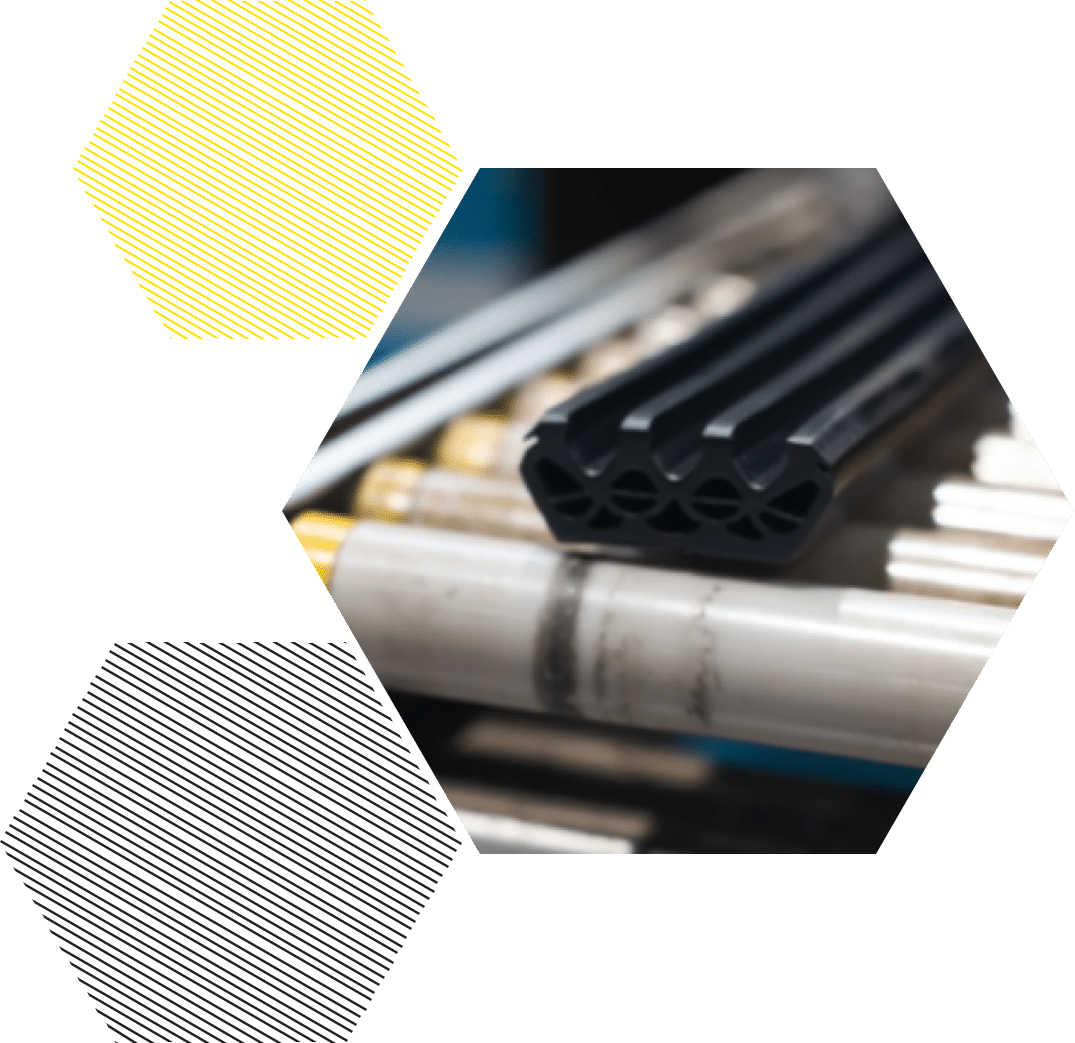

Engineering & Design

Successful custom plastic extrusions begin with a well-engineered design. Our engineers collaborate with yours to ensure the materials, manufacturing process and testing not only satisfy all application requirements, but also enhance the overall quality of your end product.

Custom Tooling

Oftentimes, custom parts have complex design specifications that can’t be accomplished with standard, off-the-shelf tooling. Our engineering and operations teams work together to develop specialized tooling to satisfy the most complicated requirements and design specifications with exceptional quality and efficacy.

Quality Control

We often function as an extension of our customers’ engineering and production teams, shipping parts directly to manufacturing lines, in-spec and on-time every time. As an ISO 9001 registered operation, our long-standing commitment to quality is evident in our daily best practices beginning with prototyping, extensive materials testing, application testing to finishing and shipping requirements.

Resources

2021 Materials Guide

The Right Material for Your Application

The proper material selection is essential to a quality job and parts that last. The integrity of your brand relies on the quality of parts we produce and the time it takes to deliver – and it all starts with selecting the right material.