Extruded Plastics for Window & Door Manufacturers

Extruded plastic is one of the most durable, cost-effective products in the country. The extrusion process makes it possible to create custom-designed extruded plastic profiles for windows and doors that stand out in the market. When you want your customers to knock on your door and peek through your windows at what you have to offer, extruded plastics give you a leg up on the competition.

Contact Custom Profiles at 229-423-2929 to learn more about the benefits of plastic extrusion for creating eye-catching designs. Our engineers are happy to tell you more about the process and possibilities.

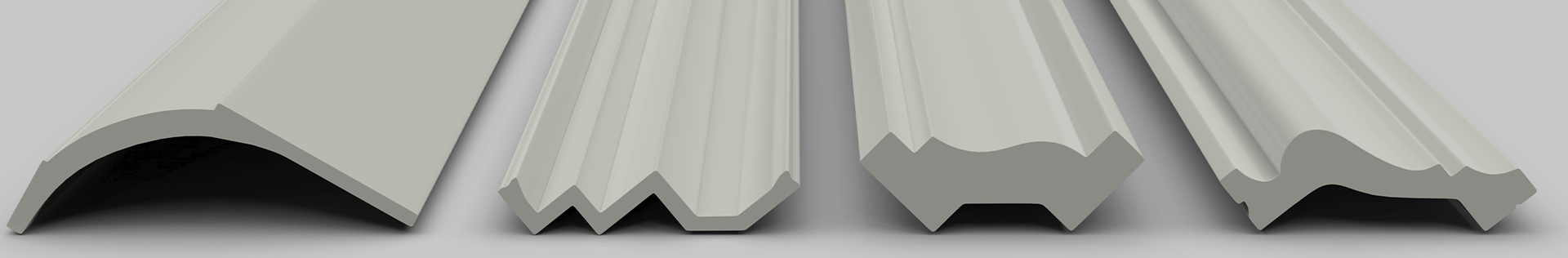

Extruded Plastic Profiles for Windows and Doors

Whether you have a simple design or a complex system you want to produce, we have the skills, experience, and equipment required to provide the extruded plastic profiles for windows and doors that your clients desire. Our internal engineering team will use state-of-the-art technology to create a cost-effective design and produce a finished product that uses the smallest amount of materials possible without sacrificing one iota of strength or durability. This helps reduce the costs associated with the production, shipping, storage, and installation.

One of the primary benefits of using extruded plastic profiles for windows and doors is that production doesn’t take long to complete. Once the design is finalized, production can occur at any time, on your schedule. This allows for just-in-time production and delivery, which reduces the overall cost and improves the efficiency of the process. Further, it also means that you can order items on demand to meet the evolving needs of your business, which helps avoid delays in delivering products to end clients.

Contact Custom Profiles at 229-423-2929 to learn more about the benefits of plastic extrusions for windows or doors. It is our pleasure to tell you more about the processes we use and the results we guarantee.

Vinyl Extrusion for Windows

The vinyl extrusion process for windows is very similar to that used for extruded plastics. As with plastics, the chlorine and ethylene composition of the vinyl can be adjusted and modified to meet your precise standards. This makes it easy to craft vinyl windows that can withstand the climate and conditions of the regions where you wish to market or install the unit.

Our engineers work closely with our clients to help identify the most efficient and effective methods of creating the desired product. Our goal is to help clients find the most efficient solutions for their needs. To that end, we use a collaborative design plan, in which our clients are actively engaged at every stage of the design and manufacturing process. This means that every detail of the vinyl extrusion is covered so that the completed extrusion looks, feels, and performs to the highest standards. Once completed, we guarantee that our vinyl extrusions will withstand rust and corrosion, will be non-conductive, and will stand up to abrasions, moisture intrusion, sunshine, and practically everything Mother Nature or the end-user can throw at it.

Contact Custom Profiles at 229-423-2929 to learn more about plastic extrusion and the products we offer for window and door manufacturers in the United States. It’s our pleasure to answer your questions and help you design and produce the products your customers depend on.