Thermoplastic Extrusions

Custom Profiles Incorporated extruded plastic products are generally component parts for other manufactured products. We are not a generic supply house that provides small quantities of typical off-the-shelf stock items. Most of the extruded parts we make are either customer- or industry-specific and are released in relatively larger quantities. We warehouse stock parts for some customers, but the majority of our products are run-to-ship items produced to satisfy customers’ just-in-time requirements. We often function as an extension of our valued customers’ production scheduling team, shipping parts based on their process projections and schedule requirements directly to their manufacturing lines, in-spec and on-time every time.

We are a quality-oriented domestic company, but we are also global in the sense that we ship the products we make all over the world. Custom Profiles Incorporated has produced parts for automobiles, automotive aftermarkets, lawn mowers, furniture, doors and windows, agricultural products, fluid-conveying systems, consumer goods, advertising POPs, and many others. We can extrude to your exact specifications:

- Shapes

- Hoses

- Tubes

- Angles

- Glazing products

- Sweeps

- Gaskets

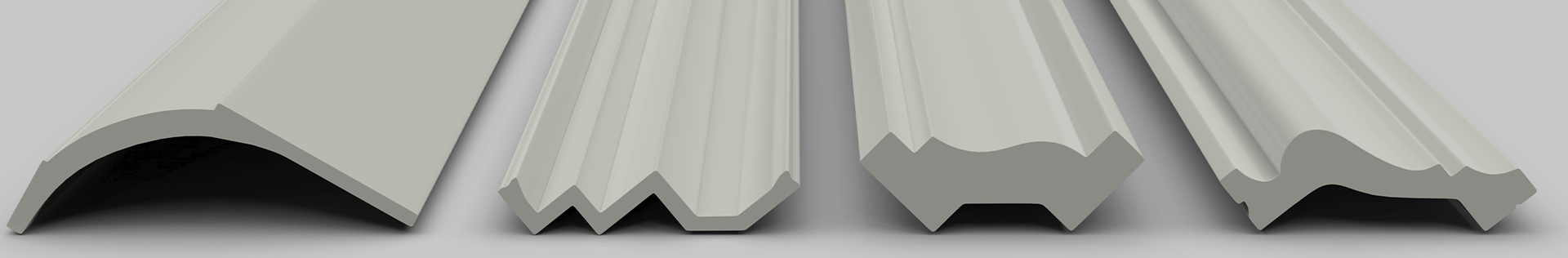

- Decorative trim

- Plus numerous other components and specialty items

A custom profile extrusion is essentially a continuous shape of a custom design in sizes ranging from 0.25” wide and .0005” thick to 12” wide and 4” thick. This is not a sheet product or injection-molded part, but a custom shape limited only by the imagination or the materials available. Custom Profiles Incorporated can make parts from a blueprint, duplicate an existing extrusion or prototype, or we can custom-design a product to satisfy your need.

At Custom Profiles Incorporated, we create unique parts that always fit. Call 229-423-2929 or contact us online now to speak to a member of our team now.

How does plastic extrusion work?

Plastic extrusion can be a little hard to understand at first. Watch the video above to see the process in action! Essentially, a raw plastic material is melted down and put through a machine that molds it into a specific shape. These shapes can be used for fencing, deck railing, window frames, and so much more.

Custom Plastic Extrusion Process

There’s a number of value-added processes we can perform during the plastic extrusion process. Here’s more information on what these processes entail:

- Dual-Durometer and Tri-Extrusion – This features multiple materials in one extrusion process.

- Cross Heading – This process helps customize the plastic extrusion process to fit your individual needs.

- Capstock – This special type of resin helps protect anything from decks and windows to pools and golf carts.

- Embossing – We can raise the texture of your product to create a design on it.

- Miter Cutting – A miter cut is an angled cut on top of two structures that allows them to join together and make a corner, or a miter joint.

To learn more about our custom plastic extrusion services and materials, check out our frequently asked questions, contact us online, or call Custom Profiles at 229-423-2929.

Pricing

Offering better prices and unmatched value isn’t a mystery of science.

At Custom Profiles Incorporated, we have a simple formula for our services:

- Highly efficient extrusion processes

- In-house engineering and tooling staff

- Warehouse space for bulk buying and storage

- Economical long-run pricing

- Quality materials for a longer-lasting, more cost-efficient product

For great service at an affordable price, trust our team at Custom Profiles Inc. We value your business and will work with you to produce excellent parts and products at a reasonable price.

Custom Profiles provides first-rate, quality-affordable rate pricing.

We specialize in affordable, high-volume extrusion products. If your volume is high enough, we offer reduced die fees and other incentives.

Contact us online today or call us at 229-423-2929 for a quote. Be sure to upload a copy of your print, if you have one available, to assist us in our quoting process. We look forward to working with you!

Get a Custom Plastic Extrusion Quote Today

At Custom Profiles Incorporated, we are dedicated to taking care of each and every one of our customers. We want to make sure all of your extruded plastic needs are met with 100% satisfaction. We use cutting-edge technology in order to create the exact type of extruded product you need. We are excited to start working with you soon!

Get in touch with Custom Profiles Incorporated today by contacting us online or giving us a call at 229-423-2929!